Arc welding (stick)

Arc welding is the process of joining 2 metals together using an electrode as the filler rod, and an electric arc to melt the metal. Arc welding or “stick welding” as it’s referred, uses a flux covered rod to weld with. Flux is a chemical coating that’s used when welding to protect the liquid weld…

Read MoreAluminium Vs. Steel Welding

One reason aluminium is different from steels when welding is that it does not exhibit colour as it approaches its melting temperature until it is raised above the melting point, at which time it will glow a dull red. When soldering or brazing aluminium with a torch, flux is used. The flux will melt as…

Read MoreHot and Cold working

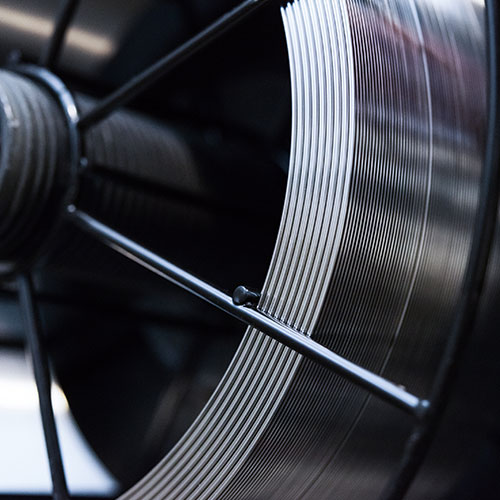

Metals can be cast to shape by melting them and pouring them into moulds. Metals can also be cut to shape by using hand tools and machine tools. However, there is the alternative of working them to shape. This is how a Blacksmith shapes metal by hammering it to shape on the anvil. Metals that…

Read MoreTitanium Welding

The properties of titanium make it an excellent choice of engineering material for a range of applications, from aerospace to chemical processing due to its high relative strength and corrosion resistance properties. These properties can be improved by alloying various elements to enhance specific properties making titanium a truly versatile engineering alloy. The chemical characteristic…

Read More